Den nevalvecavitation a ɛwɔ hɔ? Ɔkwan bɛn so na wobeyi afi hɔ?

Tianjin Tanggu Nsu-Nsɔano Valve Co., Ltd

Tianjin na ɔkyerɛwee, .CHINA

19th, .Ayɛwohomumɔ, .2023 mu

Sɛnea nnyigyei betumi anya onipa nipadua so nkɛntɛnso bɔne no, saa ara na frequency ahorow bi betumi asɛe mfiridwuma mu mfiri bere a wɔapaw control valve no yiye no, asiane a ɛkɔ soro wɔ cavitation mu, a ɛbɛma dede ne wosow kɛse aba, na ɛde paipu a ɛwɔ mu ne nea ɛwɔ ase no asɛe ntɛmntɛm yiyevalve.

Bio nso, dede a ɛkɔ soro taa ma wosow a ebetumi asɛe paipu, nnwinnade ne nnwinnade afoforoValve a wɔde yɛ adwumabere kɔ so no, nneɛma a ɛwom no sɛe, valve cavitation a pipeline nhyehyɛe no de ba no taa sɛe kɛse. Saa ɔsɛe yi fi dede a ɛwosow ahoɔden, corrosion nhyehyɛe a ɛkɔ ntɛmntɛm ne cavitation a ɛda adi wɔ dede a ɛkorɔn a ɛyɛ amplitude kɛse a ɛwosow a ɛnam nsuonwini ahurututu a ɛbɛn ne nea ɛwɔ shrinkage no ase a ɛba ne nea ɛhwe ase no so ba.

Ɛwom sɛ eyi taa ba wɔ bɔɔlbɔ mu devalve ahorow a wɔde yɛ adwumane rotary valves wɔ nipadua no mu, ebetumi aba ankasa wɔ bere tiaa bi a ɛkorɔn a ɛsan nya ahoɔden a ɛte sɛ wafer nipadua fã a ɛwɔ V-ball no mu no muvalve, nkankanwansena valve ahorowwɔ valve no fã a ɛwɔ fam no so bere avalveyɛ stressed wɔ gyinabea biako a ɛyɛ mmerɛw sɛ cavitation adeyɛ, a ɛyɛ mmerɛw sɛ leakage wɔ valve piping ne welding siesie, valve no mfata ma saa ɔfã yi line.

Ɛmfa ho sɛ ebia cavitation ba wɔ valve no mu anaasɛ valve no ase no, nnwinnade a ɛwɔ cavitation beae no bɛsɛe kɛse wɔ ultra-thin films, springs ne section nketewa cantilever structures, amplitude vibrations akɛse betumi akanyan oscillations. Wohu mmeae a ɛtaa di huammɔ wɔ nnwinnade te sɛ pressure gauges, transmitters, thermocouple sleeves, flowmeters, sampling systems Actuators, positioners ne limit switches a springs wom no bɛhaw ntɛmntɛm, na mounting brackets, fasteners ne connectors bɛsan ayɛ mmerɛw na adi nkogu esiane wosow nti.

Fretting corrosion, a ɛba wɔ nneɛma a asɛe a ɛda adi sɛ wosow ntam no abu so wɔ baabi a ɛbɛn cavitation valves. Eyi ma oxides a ɛyɛ den ba sɛ abrasives na ama nneɛma a asɛe ntam asɛe ntɛmntɛm. Nnwinnade a ɛka ho ne isolation ne check valves, de ka control valves,pumps, rotating screens, samplers ne foforo biara a ɛkyinkyini anaasɛ sliding mechanism.

Wosow a ano yɛ den nso betumi apaapae na asɛe dade valve afã horow ne paipu afasu. Dade asinasin a apete anaa nnuru a ɛporɔw betumi agu nsɛm ho amanneɛbɔ a ɛwɔ nsu afiri no mu no ho fĩ, na ebetumi anya nkɛntɛnso kɛse wɔ nsu afiri a ɛho tew a wɔde fa nsu mu ne nsu afiri a ɛho tew kɛse so. Wɔmma eyi nso ho kwan.

Nkɔmhyɛ a ɛfa cavitation huammɔdi a plug valves yɛ den kɛse na ɛnyɛ kɛkɛ akontaabu choke nhyɛso drop. Osuahu kyerɛ sɛ ebetumi aba sɛ nhyɛso a ɛwɔ asubɔnten kɛse no mu no bɛkɔ fam akodu nsu no mu nsu a ɛyɛ hyew no nhyɛso so ansa na mpɔtam hɔ nsu a ɛyɛ hyew wɔ mpɔtam hɔ na nsu a ɛyɛ hyew no abubu. Wɔn a wɔyɛ valve binom hyɛ nkɔm sɛ owiatɔe ntɛm bedi huammɔ denam nhyɛso a ɛbɛkɔ fam mfiase no a wɔbɛkyerɛkyerɛ mu no so. Ɔkwan a valve yɛfo bi fa so fi ase de hyɛ nkɔm sɛ cavitation bɛsɛe no gyina nokwasɛm a ɛyɛ sɛ steam bubbles hwe ase, na ɛde cavitation ne dede ba. Wɔakyerɛ sɛ sɛ dede dodow a wɔabu ho akontaa no sua sen anohyeto a wɔabobɔ din wɔ ase ha no a, wɔbɛkwati cavitation ɔsɛe kɛse.

Valve kɛseɛ kɔsi nsateakwaa 3 – 80 dB

Valve kɛse yɛ nsateakwaa 4-6 – 85 dB

Valve kɛse yɛ nsateakwaa 8-14 – 90 dB

Valve akɛseɛ yɛ nsateakwaa 16 ne nea ɛboro saa – 95 dB

Akwan a wɔfa so yi cavitation asɛe no fi hɔ

Valve titiriw nhyehyɛe a wɔde beyi cavitation afi hɔ no de split flow ne graded pressure drop di dwuma:

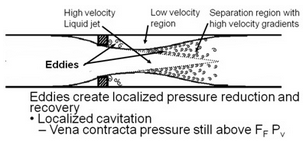

“Valve diversion” ne sɛ wɔbɛkyekyɛ nsu a ɛsen kɛse bi mu ayɛ no nsu nketenkete pii, na wɔayɛ ɔkwan a ɛsen fa valve no mu no sɛnea ɛbɛyɛ a nsu no bɛfa abue nketewa dodow bi a ɛne ne ho di nsɛ mu. Esiane sɛ wobu cavitation bubble no kɛse fã no fa abue a nsu no fa mu no so nti. Bue ketewaa no ma ahurututu nketenkete tumi ba, na ɛma dede kakraa bi na ɛba na sɛ ɛba sɛ ɛsɛe ade a, ɛnsɛe pii.

“Graded pressure drop” kyerɛ sɛ wɔayɛ valve no sɛnea ɛbɛyɛ a ebenya nsakrae mmeae abien anaa nea ɛboro saa nnidiso nnidiso, enti sɛ́ anka nhyɛso no nyinaa bɛkɔ fam wɔ anammɔn biako mu no, egye anammɔn nketenkete pii. Nea ennu ankorankoro nhyɛso a ɛba fam no betumi asiw nhyɛso a ɛwɔ shrinkage no mu no kwan sɛ nsu no mu nsu a ɛyɛ hyew nhyɛso no nkɔ fam, na ɛnam so ma adeyɛ a ɛne sɛ cavitation wɔ valve no mu no fi hɔ.

Nneɛma a wɔaka abom a wɔde diverting ne pressure drop staging wɔ valve koro no ara mu ma kwan ma cavitation resistance a ɛkɔ anim denam. Bere a wɔreyɛ valve nsakrae no, control valve no a wɔde si hɔ ne nhyɛso a ɛwɔ valve no inlet no yɛ kɛse (sɛ nhwɛso no, akyirikyiri a ɛwɔ soro, anaasɛ wɔ sorokɔ a ɛba fam), ɛtɔ mmere bi a eyi cavitation haw ahorow fi hɔ.

Afei nso, sɛ wode control valve no si beae a nsu no hyew wɔ, na ɛno nti vapor nhyɛso a ɛba fam (te sɛ ɔhyew a ɛba fam afã ɔhyew exchanger) no betumi aboa ma wɔayi cavitation haw ahorow afi hɔ.

Nsɛm a wɔaboaboa ano no ada no adi sɛ cavitation phenomenon a ɛwɔ valves mu no nyɛ degradation adwumayɛ ne ɔsɛe a ɛba valves nkutoo ho ampa. Nsuo afiri a ɛwɔ nsuo ase ne nnwinnadeɛ nso wɔ asiane mu. Cavitation a wɔbɛhyɛ ho nkɔm na wɔatu anammɔn de ayi afi hɔ nkutoo ne ɔkwan biako pɛ a wobɛfa so akwati ɔhaw a ɛne valve a wɔde di dwuma ho ka a ne bo yɛ den no.

Bere a wɔde bɛkyerɛw: Jun-25-2023