1. Nhyehyɛe mu nhwehwɛmu

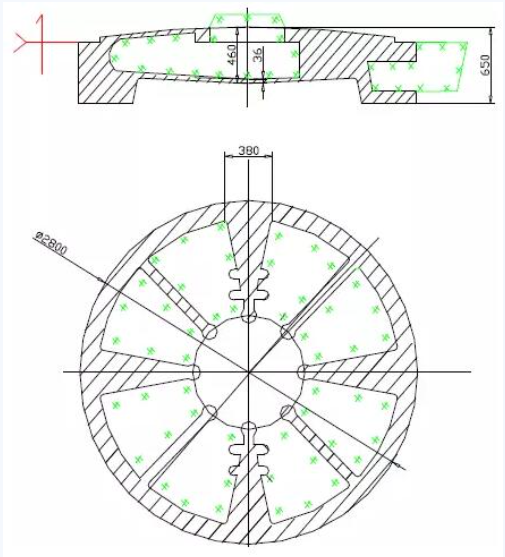

(1) Eyinwansena valvewɔ kurukuruwa a ɛte sɛ keeki, emu abura no wɔ abusuabɔ na wɔde mpampam 8 a ɛhyɛ den gyina akyi, tokuru a ɛwɔ soro Φ620 no ne emu abura no di nkitaho, na nea aka novalvewɔato mu, ɛyɛ den sɛ wobesiesie anhwea no mu na ɛnyɛ den sɛ wɔbɛsɛe no. Mframa a wɔtwe fi mu ne sɛnea wɔhohoro mu no nyinaa de nsɛnnennen kɛse ba, sɛnea wɔada no adi wɔ Mfonini 1 mu no.

Ɔfasuo a ɛwɔ castings no mu duru gu ahodoɔ kɛseɛ, ɔfasuo no mu duru a ɛkyɛn so no du 380mm, na ɔfasuo no mu duru a ɛsua koraa no yɛ 36mm pɛ. Sɛ casting no yɛ den a, nsonsonoe a ɛwɔ ɔhyew mu no yɛ kɛse, na ɛnyɛ den sɛ shrinkage a ɛnteɛ no betumi ama shrinkage cavities ne shrinkage porosity sintɔ aba, na ɛno bɛma nsu akɔ mu wɔ hydraulic sɔhwɛ no mu.

2. Adeyɛ nhyehyɛe:

. Stable, cantilever core ti a ɛwɔ ntokuru mmienu a ɛyɛ anifuraeɛ a ɛwɔ nkyɛn no tenten ware sene tokuru no tenten, ma enti anhwea no nyinaa mfimfini a ɛtwe ade ba fam no yɛ biased to the side of the core head de hwɛ hu sɛ anhwea core no ayɛ pintinn na ɛgyina pintinn.

Wɔfa nhyehyɛe a wɔde hwie gu a wɔato mu fã bi, ∑F mu: ∑F tẽẽ: ∑F tẽẽ=1:1.5:1.3, sprue no de dɔte afiri a ne mu ntwemu yɛ Φ120 di dwuma, na wɔde birikisi a ɛyɛ 200×100×40mm a ɛtumi nhyew asinasin abien gu ase na amma dade a ayɛ nwini no ankɔ tẽẽ Wɔ impact sand mold no ho no, wɔde 150×150×40 foam ceramic filter ahyɛ runner no ase, na wɔde ceramic tubes 12 a emu ntwemu yɛ Φ30 di dwuma ma emu runner no de bata casting no ase pɛpɛɛpɛ denam nsuo a wɔboaboa ano a ɛwɔ filter no ase no so ma ɛyɛ aseɛ hwie hwie gu nhyehyɛeɛ, sɛdeɛ wɔakyerɛ wɔ Mfonini 2 Essence mu no

. Anhwea adaka no kɛseɛ yɛ 3600×3600×1000/600mm, na wɔde dadeɛ mprɛte a ne kɛseɛ yɛ 25mm welded na ama ahoɔden ne denden a ɛfata, sɛdeɛ wɔakyerɛ wɔ Mfonini 3 mu no.

3. Adeyɛ a wɔde di dwuma

(1) Modeling: Ansa na modeling, fa Φ50×50mm standard sample sɔ compressive ahoɔden a resin anhwea ≥ 3.5MPa, na tighten awɔw dade ne runner no hwɛ hu sɛ anhwea nkuku no wɔ ahoɔden a ɛdɔɔso a ɛbɛma graphite a ɛba bere a molten dade solidifies Chemical ntrɛwmu, na siw molten dade no kwan sɛ ɛbɛbɔ runner fã no bere tenten sɛ ɛbɛma anhwea ahohoro.

Core a wɔyɛ: Wɔde mpampam 8 a ɛhyɛ den, a ɛnam mfinimfini abura no so na ɛka bom, akyekyɛ anhwea no mu afã horow 8 a ɛyɛ pɛ. Afã foforo biara nni hɔ a ɛboa ne nea ɛma mframa fi mu gye mfinimfini core ti no. Sɛ wɔantumi ansiesie anhwea no mu na Exhaust a, anhwea no mu a ɛtwetwe ne mframa ntokuru bɛda adi bere a wɔahwie agu akyi. Esiane sɛ anhwea no mu nyinaa sõ nti, wɔakyekyɛ mu ayɛ no afã awotwe. Ɛsɛ sɛ ɛwɔ ahoɔden ne denden a ɛdɔɔso a ɛbɛma anhwea no mu rensɛe bere a nsunsu no afi hɔ akyi, na ɛrensɛe bere a wɔahwie agu akyi. Deformation ba, sɛnea ɛbɛyɛ a wɔbɛhwɛ ahu sɛ ɔfasu no mu duru yɛ pɛ wɔ casting no mu. Esiane eyi nti, yɛyɛɛ dompe titiriw bi a ɛwɔ akyi no titiriw, na yɛde hama a ɛma mframa fa mu kyekyeree no wɔ dompe a ɛwɔ mu no so de twe mframa a efi mu ba no fi core ti no mu de hwɛ hui sɛ anhwea nkuku no bɛyɛ ketewaa bere a yɛreyɛ core no. Sɛnea wɔakyerɛ wɔ Mfonini 4 mu no.

(4) Adaka a wɔde to mu: Sɛ yesusuw sɛ ɛyɛ den sɛ wɔbɛhohoro anhwea a ɛwɔ ntontom valve no mu no ho a, wɔde paint abien na ɛyɛ anhwea no mu nyinaa, wɔde zirconium paint a wɔde nsa ayɛ (Baume degree 45-55) brush ɔfa a edi kan no, na wɔde paint gu ɔfa a edi kan no so na wɔhyew. Sɛ woyow wie a, fa magnesium paint a wɔde nsa ayɛ (Baume degree 35-45) peta ɔfa a ɛto so abien no so na amma nea wɔde agu no ankɔfa anhwea ho na ansɛe, a wontumi nsiesie. Wɔde M25 nkɔnsɔnkɔnsɔn abiɛsa asɛn Φ200 dade paipu a ɛwɔ core dompe no nhyehyɛe titiriw no so, a wɔde M25 nkɔnsɔnkɔnsɔn abiɛsa asiesie na wɔatoto mu denam soro nkuku anhwea adaka a ɛwɔ nkɔnsɔnkɔnsɔn ano na wɔahwɛ sɛ ɔfã biara ɔfasu no mu duru yɛ pɛ anaa.

4. Melting ne hwiegu nhyehyɛe

(1) Fa Benxi low-P, S, Ti high-quality Q14/16 # mprako dade di dwuma, na fa ka ho wɔ ratio a ɛyɛ 40% ~ 60%; trace elements te sɛ P, S, Ti, Cr, Pb, ne nea ɛkeka ho no yɛ katee controlled wɔ scrap dade, na no rust ne ngo ho kwan , addition ratio yɛ 25% ~ 40%; ɛsɛ sɛ wɔde tuo a wɔde bɛtow siesie charge a wɔasan de aba no ansa na wɔde adi dwuma na ama wɔahwɛ ahu sɛ charge no ho tew.

(2) Titiriw component control akyi fononoo: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (nkae): 0.035% ~ 0.05%, wɔ adwene a ɛne sɛ wɔbɛhwɛ ahu sɛ spheroidization, Mg anohyeto (residual) ɛsɛ sɛ wɔfa sɛnea ɛbɛyɛ yiye biara.

(3) Spheroidization inoculation ayaresa: wɔde magnesium a ɛba fam ne spheroidizers a ɛho yɛ na a ɛba fam di dwuma, na nea wɔde ka ho no yɛ 1.0% ~ 1.2%. Amanne kwan so flushing kwan spheroidization ayaresa, 0.15% pɛnkoro inoculation kata nodulizer wɔ package no ase, na spheroidization no wie. Afei wɔde slag no yɛ subcontract ma secondary inoculation a ɛyɛ 0.35%, na wɔyɛ flow inoculation a ɛyɛ 0.15% bere a wɔrehwie agu no.

(5) Wɔgye ɔhyew a ɛba fam ntɛmntɛm hwie guu kwan no tom, ɔhyew a wɔde hwie gu no yɛ 1320 ° C ~ 1340 ° C, na bere a wɔde hwie gu no yɛ 70 ~ 80s. Wontumi ntwitware dade a ayow no mu bere a wɔrehwie agu no, na sprue kuruwa no yɛ ma bere nyinaa na amma mframa ne nneɛma a ɛka ho no ankɔ nkuku no mu denam mmirikatufo no so. cavity a ɛwɔ abura mu.

5. Casting sɔhwɛ mu aba

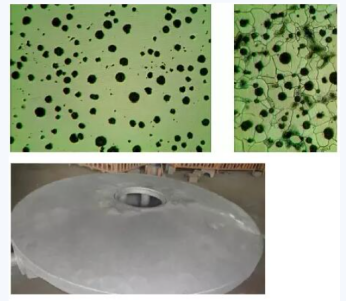

(1) Sɔ tensile ahoɔden a ɛwɔ cast sɔhwɛ block no hwɛ: 485MPa, elongation: 15%, Brinell hardness HB187.

(2) Spheroidization rate yɛ 95%, graphite kɛseɛ yɛ grade 6, na pearlite yɛ 35%. Wɔakyerɛ metallographic nhyehyɛe no wɔ Mfonini 5 mu.

(3) Wɔanhu sintɔ biara a wobetumi akyerɛw wɔ UT ne MT mfomso a ɛto so abien a wohu wɔ afã horow a ɛho hia no mu.

.

(6) 20kg/cm2 hydraulic pressure test akyi processing ankyerɛ sɛ leakage biara

6. Nsɛm a wɔde wie

Sɛnea ntontom valve yi nhyehyɛe su kyerɛ no, wodi ɔhaw a ɛne sɛ anhwea kɛse a ɛwɔ mfinimfini no a entumi nnyina na ɛnyɛ den sɛ ɛbɛsakra na ɛyɛ den sɛ wɔbɛtew anhwea ho no ho dwuma denam nhyehyɛe a wɔde bɛyɛ adwuma no a wosi so dua, anhwea no mu a wɔyɛ ne nea wɔde besiesie ne nneɛma a wɔde zirconium ayɛ a wɔde bedi dwuma no so. Mframa ntokuru a wɔde si hɔ no kwati sɛ ebetumi aba sɛ ntini a ɛwɔ castings mu no bɛba. Efi fononoo charge control ne runner nhyehyɛe, foam ceramic filter screen ne ceramic ingate mfiridwuma na wɔde di dwuma de hwɛ hu sɛ dade a wɔabɔ no ho tew. Afei mpɛn pii inoculation ayaresa, metallographic nhyehyɛe a castings ne ahorow The comprehensive adwumayɛ adu gyinapɛn ahwehwɛde ahorow a adetɔfo

FiriTianjin Tanggu Nsu-nsɔano valve Co.,ltd. Nwansena valve, apon ano valve, . Y-a wɔde hyɛ mu, wafer abien mprɛte nhwehwɛmu valvea wɔyɛ.

Bere a wɔde bɛkyerɛw: Apr-29-2023